Schlenk lines

- Two separated Schlenk lines (8 reaction stands) equipped with Vacumbrandt RZ6 rotary vane vacum pumps, DCP 3000 vacuum gauges

- Reaction temerature control with Juchheim LTR 2500 digital controllers

- Inert N2 o Ar atmosphere

- Winkler heating mantles

- Pressure control with air anti-return valves

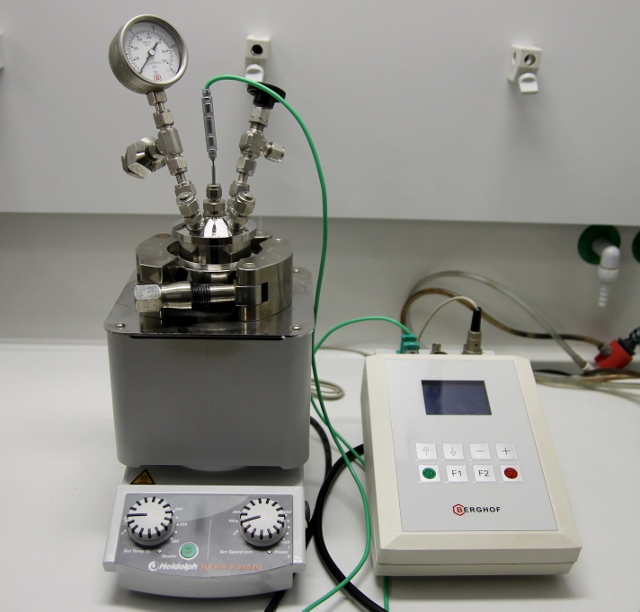

Reactor Berghof BR-100

- High-pressure reactor equipped with magnetic stirrer and hot plate used as a system for hydrothermal/solvothermal syntheses.

- Pressure max.: 200 bar, temperature max. 250°C

- Simple heating and stirring using a heating plate with heater block and magnetic bars

- Volume of vessel: 100 ml

- The reactor is locked with a quick-lock chain that is manually applied, without the need for tools

- As an option is a liquid and/or gas sample extraction device

- Ractor is equipped with advanced temperature controller

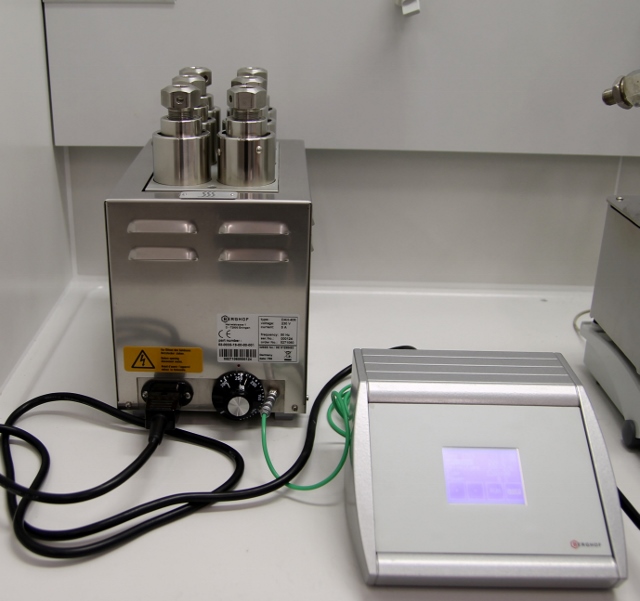

Reactor Berghof DAB-2

- A modular system applied to synthesis in up to six stainleess vessels under hydrothermal/solvothermal conditions at the same time.

- Pressure max. 200 bar, temperature max. 250°C

- Heating on a hot plate

- Volume of vessels: 50 ml, number of vessels: max. 6

- Rupture discs in each pressure vessel

- PTFE-inserts may be used for storage of reaction mixtures

- Easy handling

- Tool-free opening and closure of quick release closures (tensioning rings and chains)

- Swagelok connections which can be opened and closed by the operator

- No crosses and T-pieces in valves and fittings which simplifies cleaning of all part

Reactor Haas HA BL12 with HYD-50 vessels

- A modular system applied to synthesis in up to twelve stainless steel 304 vessels under hydrothermal/solvothermal conditions at the same time.

- Teflon liner allows using pressure max. 30 bar, temperature max. 230°C; PPL liner allows to use temperature max. 280°C

- The volume of vessels: 50 ml, number of vessels: 12

- Heating on a hot plate with programmable time and temperature

- Heating rate 5℃/ min

- Possible water cooling

- Tool-free opening and closing

- Simple design for easy cleaning

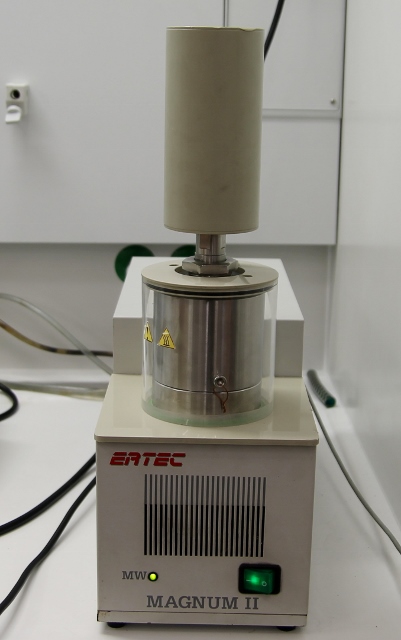

Reactor Ertec Magnum II

- A laboratory device used for the chemical synthesis in Teflon containers at increased temperature and pressure. The processes are accelerated by the presence of the microwave energy.

- Temperature max. 300ºC

- Pressure max. 5MPa (50 bar)

- Capacity of vessels: 108 cm3

- Cooling pressure head: Water

- The possibility of carrying out the reaction while controlling the power reflected from the sample in a Teflon vessel.

- Monitoring the reaction temperatures and pressures.

Solvothermal reactor – Amar Equipments

- Reactor with magnetic stirring for preparing materials (e.g.: metal or oxide nanoparticles) under high-pressure and temperature condition.

- The device is equipped with a heating controler with a timer, which allows to program multiple temperatures and heating times for a single reaction. Reactor can be pre-filled with argon (up to ~10 bar) or nitrogen (up to ~45 bar).

- Max. operating temperature: 200oC

- Max. operating pressure: 200 bar

- Teflon vessel volume: ~200 mL

Reactor HRTJ (for large volumes)

- A single-vessel, stainless steel SS316, hydrothermal/solvothermal reactor

- Temperature max. 175°C

- The volume of the Teflon-lined vessel: 750 ml

- Electric heating

- Magnetic stirring

- Digital temperature controller

Nabertherm Muffle Furnace LT 15/13/P330

- max. temp.: 1300°C

- minutes to Tmax: 60

- working temp.: 0 to 40°C

- storage temp.: -20°C to 75°C

- volume: 15 L

- power: 3.8 kW

- heating from two sides

- exhaust air outlet in rear wall of furnace

- real time clock

Tube furnace with reducing atmosphere

- Compact tube furnaces Nabertherm R 50/500/12 with integrated control systems equipped with gas supply system for non-flammable, protective or reactive gases (e.g. Ar, N2, H2/N2 5/95)/vacuum operations (vacuum pump Pascal 2005, SD Version with pumping speed at 50 Hz 5 m³/h).

- Tmax 1200 °C

- Outer tube diameter of 50 mm, heated length 500 mm

- Ceramic working tube C610 (gastight, heat-up/cool-down ramp max. 300 K/h) with 2 vacuum-tight, water-cooled stainless steel flanges of 1.4301 with fittings on the outlet side.

- Thermocouple type N

- Controller B410 (5 programs with each 4 segments).

Memmert Universal Oven UN55

- temp. range: 5°C to 300°C

- internals: 1 stainless steel grid, large-area heating of four sides

- interior dimensions: 400 x 400 x 300 mm- external dimensions approx.: 730 x 950 x 670 mm

- max. loading of chamber: 80 kg

- volume: 53 L- weight: 57 kg

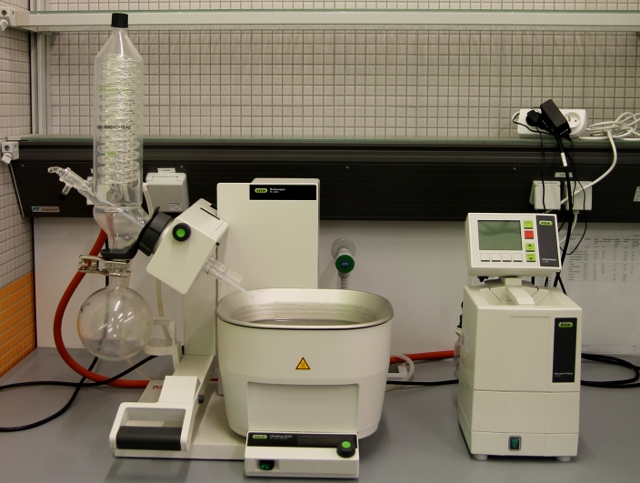

Rotary evaporator Rotavapor R-300 BUCHI

- Vacuum pump V-100 and

- Vacuum controller I-100

- Water/oil bath B-305 (20-220 st. Cel. 5L)

- Vertical condenser type V

- Plastic cover P+G

- Power supply 220-240V

- efficiency 1,5 m3/h

- absolute final vacuum , <10 mbar

- manual lift

- flask rotation controller

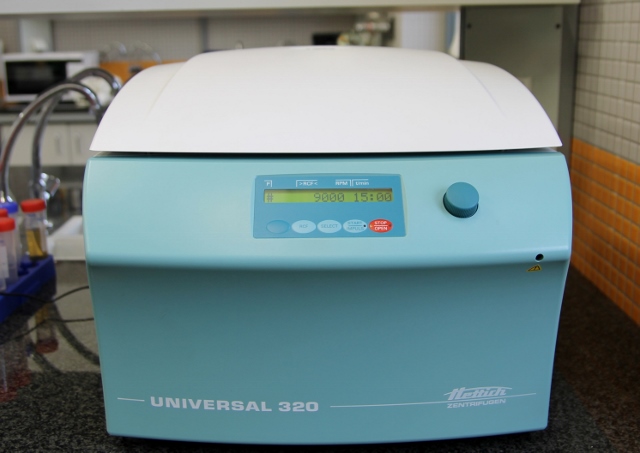

Centrifuge Hettich Zentrifugen Universal 320 (classic)

- power supply: 200-240 V 1~

- frequency: 50-60 Hz

- consumption: 400 VA

- emission, immunity: EN/IEC 61326-1, class B

- max. capacity: 8 x 85 mL / 4 x 100 mL / 32 x 15 mL

- max. RPM (speed): 15000 min-1 (4000 min-1 – room 3.115)

- max. RCF: 21382- running time: 1 sec – 99 min, continuous run, short cycle mode (impulse key)

- dimensions: 346 x 395 x 520 mm- weight: 31 kg

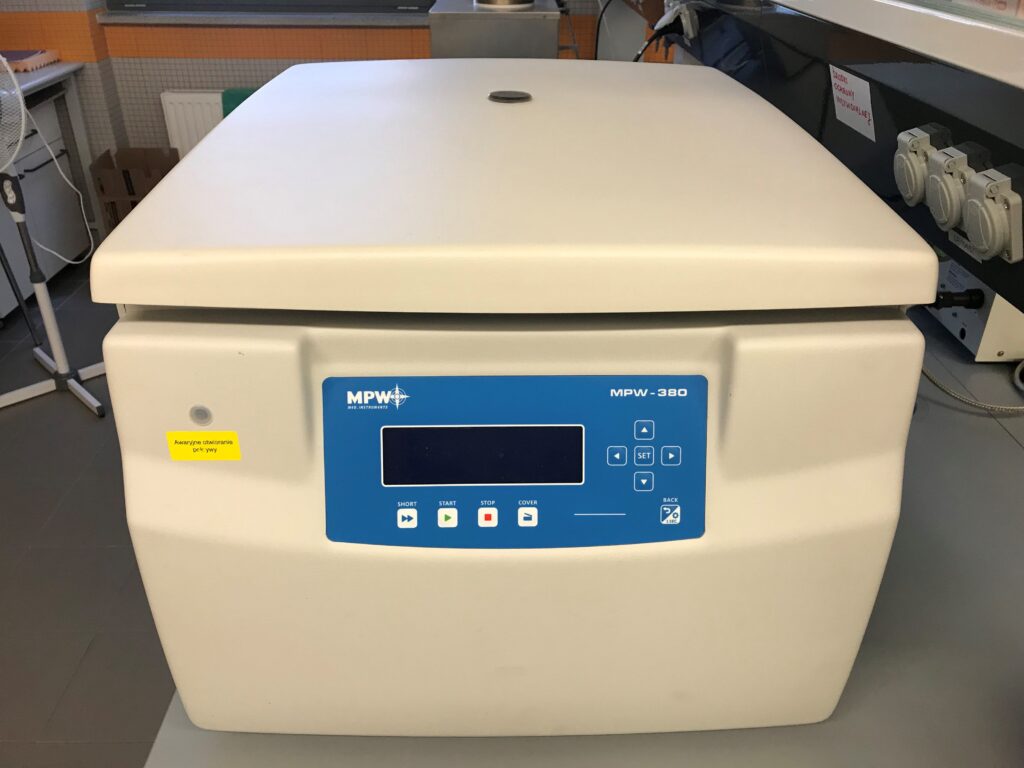

Centrifuge MPW 380 (for large volumes)

- power supply: 230 V; 50/60 Hz

- Capacity: 2 x 250 mL

- max. RPM (revolutions per minute): 90 ÷ 18 000

Retsch Ultra Centrifugal Mill ZM 300 and Retsch Cryomill

Complete grinding station, including grinding at liquid nitrogen temperature.

ZM 300

- Rotor mills are used for the rapid fine comminution of soft to medium-hard as well as temperature-sensitive or fibrous materials.

- The powerful ZM 300 ultra-centrifugal mill offers maximum size reduction performance and ease of operation.

- The variable speed of 6,000-23,000 min-1 enables sample preparation in the shortest possible time that is gentle on the material and suitable for analysis.

Cryomill

- The CryoMill is tailored for cryogenic grinding. The grinding jar is continually cooled with liquid nitrogen from the integrated cooling system before and during the grinding process. Thus the sample is embrittled and volatile components are preserved. The liquid nitrogen circulates through the system and is continually replenished from an Autofill system in the exact amount which is required to keep the temperature at -196 °C. Powerful impact ball milling results in a perfect grinding efficiency. The Autofill system avoids direct contact with LN2 and makes the operation very safe. Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 ml.

- Application Examples: animal feed, bones, chemical products, food, hair, oil seeds, paper, plant materials, plastics, sewage sludge, soils, tablets, textiles, tissue, waste samples, wood, wool, etc.

- Product Advantages

- powerful cryogenic grinding by impact and friction, up to 30 Hz

- 3 different grinding modes (cryogenic, dry or wet at ambient temperature)

- closed LN2-system (autofill) for enhanced safety, avoids any contact of the user with LN2

- screw-top grinding jars for convenient, leak-proof operation

- wide range of accessories including various LN2 feeding systems, jar and ball sizes, adapter racks, materials

- low LN2-consumption

- clearly structured user interface, memory for 9 SOPs

- programmable cooling and grinding cycles (10 s to 99 min)